|

|

Water Pump Troubleshooting Series of the Topic: Abnormal Temperature RiseThe service life of the water pump is inseparable from regular inspections. The inspection process is mainly to judge the condition of the water pump through the external operation performance of the water pump, so as to find the abnormality of the water pump. Most abnormalities are not caused by irreversible damage to the pump. If the fault can be diagnosed and maintained in the first place, the pump can be restored to normal operation. The abnormal water pump mainly has the following five manifestations: Abnormal noise Abnormal vibration Abnormal performance Abnormal temperature rise Other abnormalities Water pumps are electromechanical products, and they must generate heat during operation. The sources of heat include the physical friction of the medium in the pump body, the heat generated by the rotating friction of the bearing, and the heat generated by the resistance of the motor stator and rotor. It is normal for the water pump to generate heat, but when the heat generation is too large and the temperature rises too high, the life of the water pump will decrease or even be damaged. Regarding the temperature rise of the water pump, there is a grade mark on the nameplate, written as insulation grade, and its grade is indicated by letters. The insulation grades specified in the standard are A, E, B, F, and H, which indicate the resistance of different motors to temperature rise. Among them, the F grade is used more, and the H grade is the highest. The abnormal temperature rise of the water pump will be manifested in two places, the temperature rise of the pump head and the temperature rise of the motor. Most of the reasons for the abnormal temperature rise come from: Medium is overheated In some systems, the water pump will deliver high-temperature media. When the temperature of the medium does not exceed the allowable temperature of the pump, the temperature rise of the pump can be effectively controlled. However, when the temperature of the medium exceeds the allowable temperature of the pump, the pump head will overheat, and if the motor is In the case of a long-shaft motor or a sleeve-shaft motor, the medium will transfer heat to the motor rotor through the pump shaft, aggravating the internal temperature rise of the motor, and causing double overheating of the pump head and the motor.

In this case, the temperature of the surface of the pump casing can be measured by using a temperature measuring gun. The thermal conductivity of the metal is better, and the external temperature of the pump casing is similar to the temperature of the medium. When it is confirmed that the medium exceeds the allowable temperature of the water pump, the medium needs to be cooled to avoid high temperature damage to the water pump. The parts of the water pump that are easily damaged by the high temperature medium include mechanical seals and motors. Low flow operation When the water pump is put into use, the outlet valve is open for a long time and the water pump is always running at a small flow rate, or the outlet valve is closed, but there is no control loop to turn off the water pump, causing the water pump to keep running. These two situations are called "Punch the boring pump." When running at a small flow rate, the medium in the pump body is rubbed and heated by the impeller many times. The amount of water flowing out of the pump body is very small, and the amount of heat that can be carried away is very small. More heat remains in the pump body, causing the pump body to continue. The temperature rises, the final temperature is too high, and the medium vaporization causes dry grinding of the mechanical seal or high temperature damage to the pump casing castings, resulting in damage to the water pump.

Find the abnormality of the small flow operation in time, open the outlet valve to increase the water flow of the pump, and quickly reduce the temperature of the pump casing, so that the pump can operate normally. For the planned small flow operation, please use frequency conversion to control the water pump or increase the return pipe to protect the water pump. Mechanical friction The mechanical friction mentioned here does not refer to the friction of the bearing part, but refers to the abnormal friction inside the pump, such as particulate impurities in the pump casing, grinding in the gap of the mouth ring, or pipe welding waste entering the pump body Internally, friction is generated between the impeller cover and the pump casing. This kind of friction may not generate high heat by itself and will not cause a significant temperature rise inside the pump casing. However, for low-power water pumps, it may increase the running resistance of the pump, overload the motor, and cause abnormal temperature rise of the motor.

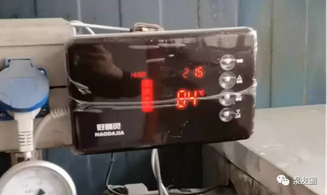

The friction caused by the entry of foreign matter needs to disassemble the water pump to clean the foreign matter, and the parts that have been frictionally damaged need to be replaced. It can be seen from this point that the overhaul of the water pump is a process of comprehensively analyzing the cause of the problem, not just a headache. Voltage is too low In some remote areas or places where the grid voltage is unstable, the pump access voltage may be lower than the motor limit value. According to the domestic voltage specifications, the single-phase power supply is 220V, and the three-phase power supply is 380V. According to the IEC60034 standard for motors, the motor can be Continuously working within ¡À5% of the rated voltage. If the voltage drops more than this ratio, the internal current of the motor will be too large, which will increase the temperature rise of the stator and rotor resistance, which will eventually manifest as an abnormal temperature rise of the motor.

In this case, you can use a multimeter to measure the phase-line voltage. When the voltage is lower than the allowable value, the grid voltage needs to be adjusted.

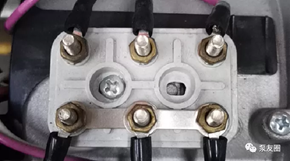

Wiring error Wiring error means that the three-phase motor uses the wrong star-corner connection when wiring. Most of the abnormal temperature rise of the motor is the voltage of the star connection for the corner connection, which causes the phase-to-phase voltage to rise and the operating current to rise. , Make the motor temperature rise abnormally, and then damage the motor.

Most motor nameplates or inside the wire box cover will mark the corresponding voltage wiring method. You need to verify the power supply voltage and use the correct star-angle connection. Poor heat dissipation There are many reasons for poor heat dissipation. The common reasons are roughly summarized as follows: (1) The ambient temperature is too high. Because the water pump is installed inside a closed box, the air temperature inside the box rises rapidly under direct sunlight in summer. When the temperature of the working environment of the water pump exceeds the allowable temperature of the motor, the motor fan of the water pump will cool down. The effect begins to decline, so that the heat generated by the normal operation of the motor cannot be dissipated in time, and the motor overheats when it runs for a long time. (2) The fan cover window of the motor is blocked. When the tail of the motor is close to obstacles, or outdoor plastic bags are adsorbed on the fan cover window, the fan cannot provide effective ventilation to blow away the cooling ribs of the motor, causing the motor to continue The problem of temperature rise will also cause the motor to overheat.

(3) The motor fan cover is missing. The cooling fan is like a water pump impeller. It needs a certain flow channel to provide ventilation. The fan cover is the "pump shell" of the fan. Centrifugal fan blades require the presence of a fan cover to produce a shaft. When there is no fan cover, the fan loses the ability to blow away the cooling ribs of the motor, causing the motor to overheat. (4) The heat dissipation ribs of the motor are covered by oil stains. When the pump is running in a poor environment and oil stains exist, the oil stains will adhere to the surface of the heat dissipation ribs of the motor. Due to the characteristics of oil, it will block the external heat exchange of the heat dissipation ribs, and the normal air volume will blow it away. The cooling capacity of the cooling ribs is greatly reduced, which will also cause the motor to overheat. Pump overload For pumps with single-stage impellers, the shaft power curve is usually a single increase. The greater the flow, the greater the power. Therefore, the operating condition point determined during the model selection and the selected motor can only ensure that the operating condition point to the left is normal operation , When the system door is too open and the resistance is too small, the pump operating point will shift to the right, causing the shaft power to increase. The shaft power after the increase may exceed the motor rated power, causing the motor to have a problem with a small horse-drawn cart . If the motor overload is caused by the deviation of the operating point, the system valve opening should be trimmed, and the system resistance curve should be placed to the left of the design operating point.

Frequent start and stop The current of motor products is relatively large at the moment of starting, and the motor running at power frequency can even reach 6~7 times the rated current at the moment of starting. Excessive current will aggravate the temperature rise of the motor in a short period of time. If frequent starting occurs, the temperature of the motor will rise. Will rise quickly. There are generally two reasons for the frequent start and stop of the motor: (1) Pressure setting problem. When the system setting pressure is not right, the pump may be stopped. The inlet water pressure is lower than the starting pressure of the pump, and the pump needs to be started. However, after the pump is started, the actual water consumption is small, causing the pump to fail. The superimposed value of the head and the inlet pipe network pressure quickly exceeds the stop pump pressure, and the water pump stops immediately, causing the problem of starting and stopping. (2) The problem of system leakage. When there is leakage in the system, even if there is no human water, the pressure at the outlet of the water pump will continuously drop, causing the pump to start periodically. When the pressure relief rate is faster, the start of the pump will change. Is more frequent. |