|

Water Pump Troubleshooting Series Topics: Abnormal PerformanceWater Pump Troubleshooting Series Topics: Abnormal Performance

The service life of the water pump is inseparable from regular inspections. The inspection process is mainly to judge the condition of the water pump through the external operation performance of the water pump, so as to find the abnormality of the water pump. Most abnormalities are not caused by irreversible damage to the pump. If the fault can be diagnosed and maintained in the first place, the pump can be restored to normal operation. The abnormal water pump mainly has the following five manifestations: Abnormal noise Abnormal vibration Abnormal performance Abnormal temperature rise Other abnormalities Most of the abnormal performance is not found in the pump itself, but manifested by other parts of the upstream and downstream of the pump system, such as the low flow rate of the faucet at the end of the pump system, the high temperature and high pressure alarm of the upstream heat source host, and the poor heating effect of the downstream fan or floor heating. and many more. For abnormal performance detected externally, the final manifestation is that the flow or head on the pump does not match the design. The reasons for this situation are usually: The pump is not exhausted Exhaust is a necessary step for the initial installation of the water pump. If there is no exhaust or the exhaust is not clean, it will cause the phenomenon of mixed air and water in the pump body. When there is continuous gas in the pump body that cannot be discharged, the performance curve of the water pump will be attenuated and the flow and head will drop. You can open the vent screw when the pump is stopped. If gas escapes, or gas escapes after filling, it can be judged that the pump body has gas. In this case, the pump should be exhausted completely or the pump should be completely filled to make the pump body After being filled with water, close the exhaust screw and run the water pump. In some cases, there will be gas in the suction pipe of the water pump, and the problem can be solved by exhausting or filling the pump many times.

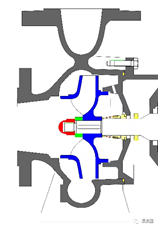

Cavitation Cavitation has been mentioned in the previous content. In addition to causing vibration and noise of the water pump, cavitation also affects the performance of the water pump. This is because during the cavitation process, the impeller suction port presents a mixed state of air and water, and the presence of air bubbles reduces the cross-sectional area of the inlet flow channel, causing the flow velocity in local areas to increase, generating vortexes, and affecting the performance of the pump. As the characteristic of cavitation changes with the flow of the pump, when the outlet valve is gradually closed, the measured performance of the pump and the curve performance will narrow the gap, until it is turned down to a certain angle or fully closed, the pump performance will be consistent with the curve. The cavitation can be judged by this point of the characteristic curve. There are many ways to solve cavitation, but they are more difficult to achieve, such as reducing the temperature of the medium, increasing the diameter of the inlet pipe to reduce resistance, reducing the length of the inlet pipe to reduce resistance, and reducing the opening of the outlet valve. Air blockage The problem of air blockage mostly occurs in the sewage pump system. When the sewage pump stops, the liquid level drops below the impeller. When the water comes in for the second time, the water pump and the outlet pipe are blocked by gas, causing the water level inside the pump body to not rise to The height of the impeller. At this time, the pump will cause the impeller to run dry without contact with water. In this case, the running current of the water pump is small, and the current can be used to judge the air blockage problem. To solve the air blockage, it is necessary to open a vent hole on the pipe section from the pump outlet to the check valve to drain the gas inside the pump body. Pump body swelling There is a similarity between the cavity of the pump body and the unvented water pump. Both are in the phenomenon of mixed air and water in the pump body. However, the key difference lies in the internal structure and installation angle of the pump body. Or exhaust exhaust, which can be analyzed and confirmed through the system structure. When the water pump is in the cavity of the pump body, the installation angle of the water pump needs to be changed to make it installed correctly, and then the problem can be eliminated by exhausting or filling the pump.

Motor reverse For water pumps with three-phase motors, the motor steering is an error-prone place. When the motor steering is not verified in the debugging, the pump may reverse. The reverse will cause the pump performance to decline sharply and fail to provide effective flow and head. You can check whether the water pump reverses by observing the rotation of the motor. The correct rotation can be viewed from the external mark of the pump body, or can be identified according to the appearance of the pump head and the appearance of the impeller. For the problem of motor reverse rotation, it can be realized by changing any two phase wire sequence. If the water pump is driven by a frequency converter, changing the direction of rotation needs to adjust the wiring sequence between the motor and the frequency converter, or use the parameter adjustment of the frequency converter. Impeller falling When water hammer frequently occurs in the system, the impeller may reverse and loosen and eventually fall. After the impeller falls, the operation of the water pump will not be able to drive the impeller to work on the water. Naturally, there is no flow and lift performance. At this time, the motor The current of is roughly the no-load current, and the current can be used to assist in judging this problem. The repair of the impeller falling is relatively simple, just disassemble the pump body and reinstall it, but the key point is how to judge the cause of the fall and avoid falling again.

System resistance does not match In some systems, the performance of the pump itself meets the design parameters, but the system does not reach the design operating point when the system is running. This problem may be on the system rather than the pump. It may be that the resistance of the system deviates too much from the design operating point. Caused. For example, the design of a circulatory system has too thin piping and more elbow valves, resulting in a steep resistance curve. Even if the valve is fully opened, the resistance of the piping cannot be reduced, resulting in the water flow rate being lower than the design value. In this case, through the adjustment of the valve, it is found that the operating point of the pump can only work on the left section of the curve, and the system needs to be modified to reduce the system resistance to release the pump flow.

Performance check point error In rare cases, the abnormal performance of the water pump that we have seen is not really abnormal. It may be a "misjudgment" caused by the wrong collection point of the flow and head. This kind of error mostly comes from the data feedback of the pressure gauge or pressure sensor. When we use the pressure gauge/pressure sensor at the wrong point, the pump head read may be consumed by resistance elements such as valves or check valves. The data may be lower than the true head of the pump. It is necessary to judge whether there is a problem of inaccurate head calculation according to the position of the pressure point of the system, and measure the pressure value near the inlet and outlet of the water pump.

Controller setting error Some water pumps with frequency conversion control usually allow setting of pressure or frequency to achieve the effect of frequency reduction and energy saving. However, if the pressure or frequency is set too low, it may cause insufficient water output performance of the pump. In this case, only the frequency converter is required. Correct settings can solve the problem. Speed is too low Different from the error problem of the frequency setting of the inverter, when the motor is replaced, a low-speed motor is used incorrectly, which causes the speed of the water pump to drop and affects the water output performance. The actual speed of the motor can be found on the motor nameplate, and the correct speed can be found according to the pump nameplate or pump data. When the speed difference is too large, the motor needs to be replaced with a suitable speed. Impeller assembly error The impeller assembly errors are more common in the on-site disassembly and maintenance of the water pump. The impeller assembly sequence is wrong, the positioning sleeve is installed in the wrong position, which causes the impeller to move axially, the structure of the orifice ring is destroyed, and a large amount of backflow occurs at the impeller suction port. , The flow rate and head are both lost, and the pump efficiency drops. For this kind of problem, it is necessary to disassemble the pump head and measure the installation size of the impeller to check. If it is indeed an installation error, it needs to be reinstalled. Impeller damage Due to long-term cavitation or foreign matter entering the pump body, the impeller is worn out, and the blades and cover plates are damaged by lack of meat and penetration, which will affect the hydraulic performance of the impeller and cause the attenuation of the flow head. This kind of damage is difficult to judge from the outside, and the pump head needs to be disassembled to inspect the impeller. For severely damaged impellers, they need to be replaced. It is not difficult to replace the impeller, but it is still necessary to check the reasons for the impeller damage to avoid re-damage in the future. Regular inspections allow us to find abnormalities in the pump as early as possible, find the cause and deal with it in a timely manner to reduce costs. However, most people cannot accurately find the cause of the abnormality in the pump, resulting in low efficiency or even damage to the pump. |